Automation of Calibration & Cutting-Edge Metrology Engineering Tools

Metrology Process Studio (MPS)

Metrology

Process Studio (MPS)

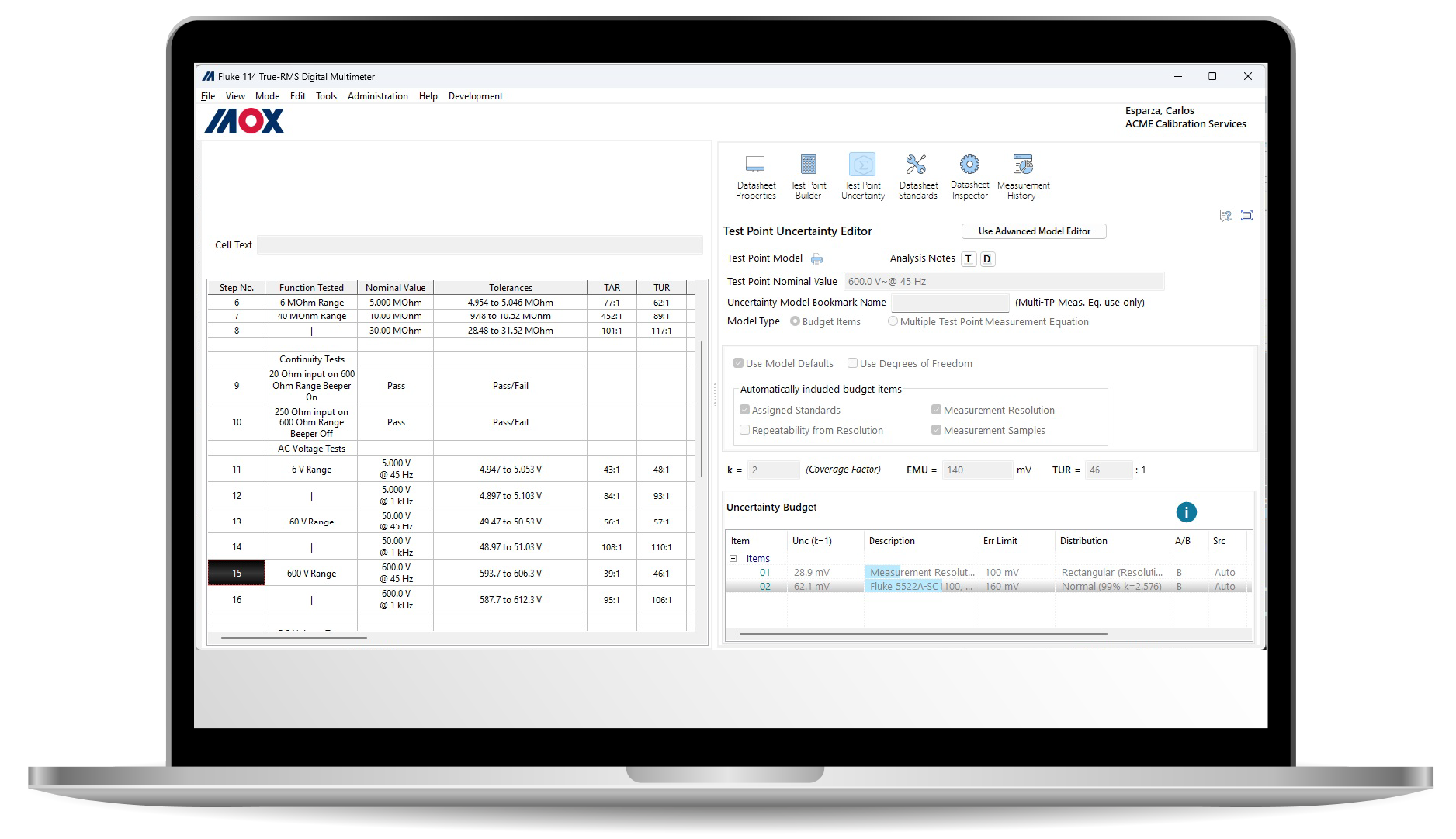

MPS is the calibration module of MOX and is used to perform manual and automated calibrations. The system has cutting-edge tools that automate many complex metrology engineering tasks such as calculating uncertainty (EMU) and test ratios (TAR/TUR).

Automated Uncertainty Modeling

MPS state-of-the-art features automate many metrology engineering tasks. MPS automatically calculates uncertainty (EMU) and test ratios (TAR/TUR) using specifications and other parameters from a test instrument’s set point, the standards used, and measurement system configuration.

The system supports multiple pre-assigned standards that can be selected at the time of calibration; the actual uncertainty and test ratios reflect the selected standard. One of MOX’s advanced features is the MetSpec module, which is used to create instrument specification files in a database format, with accuracy specifications organized by function and range limits.

MPS uses these instrument specifications to calculate accuracy and uncertainty for calibration standards. Using the MetSpec instrument specification’s function and range limit data, MPS can automatically assign the most accurate qualifying instrument range for calibration standards to the data sheet test points.

The MetSpec electronic instrument specifications can be assigned as default/alternate calibration standards and automatically integrated into the test point uncertainty models.

MPS’ default uncertainty model automatically and dynamically creates and updates uncertainty elements for each of the following:

- Standard deviation of calibration samples (Type A)

- MetSpec instrument calibration standards used (Type B)

- Measurement resolution (Type B)

- Measurement repeatability (Type B)

Users can disable any of the automatic features and manually create and modify uncertainty elements. Additional elements can also be manually added to supplement those managed by the automatic features.

Automatic Guard Banding

MPS provides the option to automatically implement one of its supported guard banding methods (NCSLI RP-10, ANSI Z540.3, RSS) at the configured risk threshold. Test Ratios (TAR/TUR), Estimated Measurement Uncertainty (EMU), and Risk are all based on the actual standards used when performing the calibration. Guard banding decisions are made dynamically based on the conditions present at the time of the actual measurement.

MetSpec

MetSpec is a library of instrument specifications in electronic format used by MPS to perform a number of unique functions, such as building calibration test points and calculating measurement uncertainties of calibration standards. MetSpec is also used to create reference Units of Measure and their conversion equations to and from the base unit. The Units of Measure system is used to perform real time conversion of accuracy and parametric matching criteria values between data sheet test points and calibration standard instrument ranges.

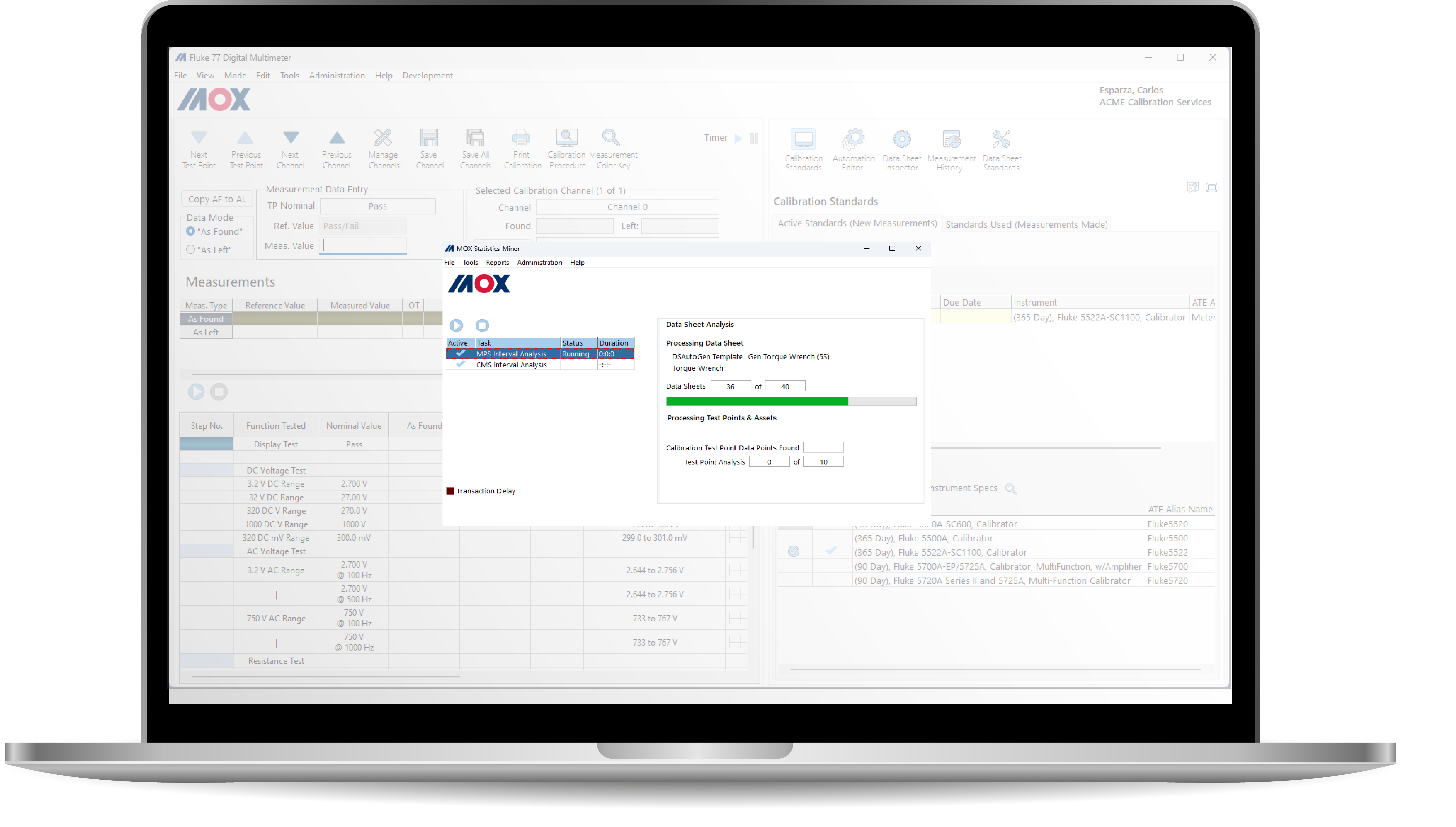

Statistics Miner

The MPS Statistics Miner uses the Method A3 to perform interval and reliability analysis and generates summary reports on the entire inventory of calibrated assets using actual measurement history, providing critical information to your engineering team in making decisions that:

- Lengthen calibration intervals, thus reducing calibration costs within the target risk envelope.

- Shorten calibration intervals, thus reducing calibration risk to production processes by maintaining the reliability of M&TE within the target risk envelope.

- Use M&TE and calibration standard equipment reliability data to support purchasing decisions related to equipment reliability.

Other Features

Fine-grained reverse traceability to pinpoint out-of-tolerance impacts

MPS performs reverse traceability for calibration standard range usage to identify specific calibration test points that might be potentially impacted by a calibration standard that fails calibration.

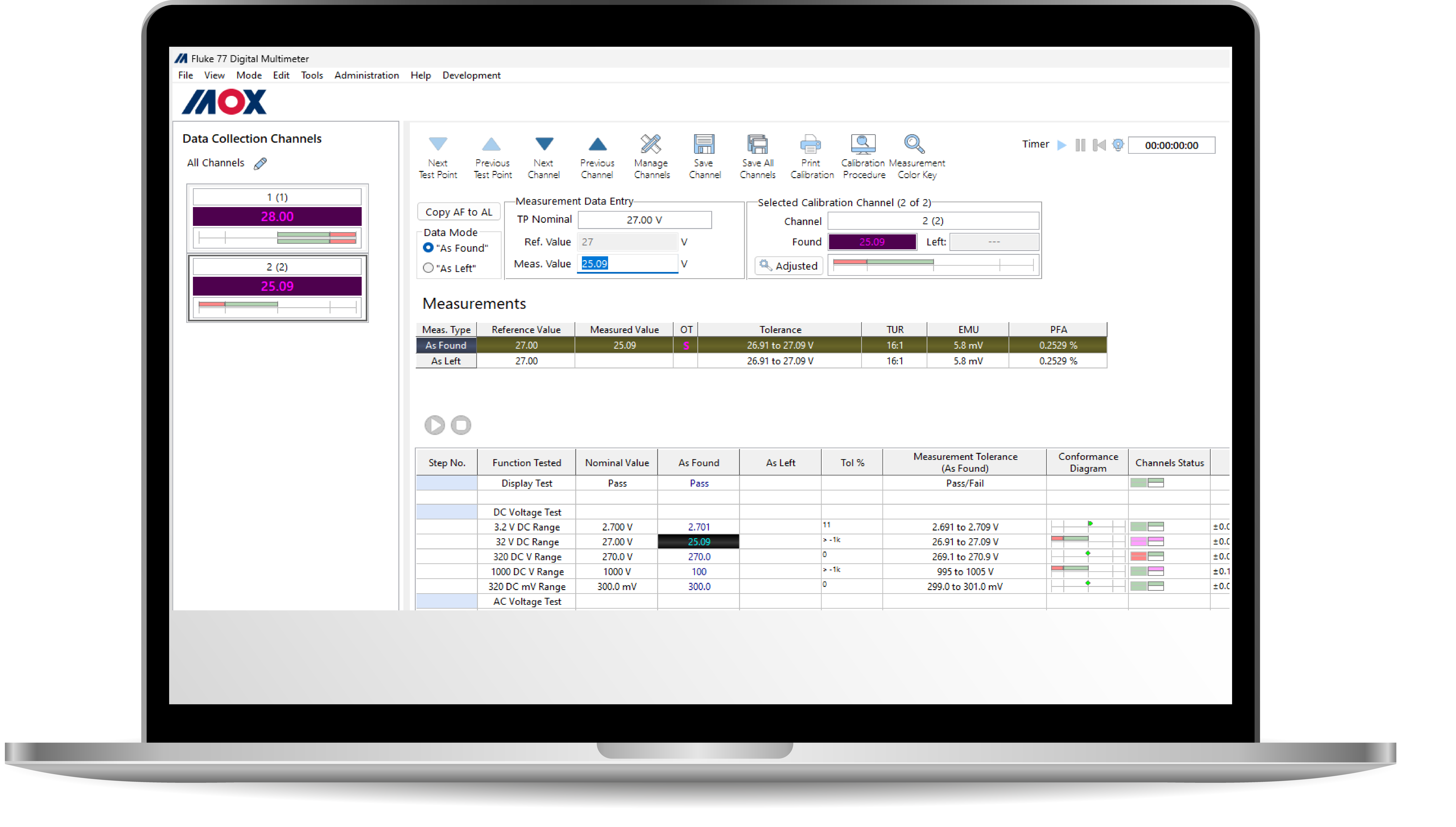

Calibrate multiple test instruments at the same time

MPS allows concurrent calibration data collection for multiple test instruments. When multiple test instruments are being calibrated together, commands are available to select the currently active channel, obtain information from one or more channels, and permanently store raw data in a channel.

Instrument sampling integration

MPS can be configured to automatically include standard deviation of the test point samples as a “Type A” uncertainty element.

Automatic detection of “Out of Tolerance” conditions

MPS automatically computes and graphically displays the relationship of the measured values to reference value, tolerance, and guard band indeterminate region, when applicable. MPS also indicates the percentage of the tolerance band consumed by the deviation between the measured and reference values.

Independent reference data for “As Found” and “As Left” measurements

MPS measurements have a child relationship to test points, allowing each measurement to have independent references such as Reference (True) Value, tolerance, standards used, and uncertainty model. This also allows users to change calibration standards during a calibration without affecting measurements already made.

COM server applications

MPS communicates with component object model (COM) server applications, allowing users to incorporate custom plugins or other applications such as Microsoft Excel into MPS calibrations.

MOX makes

easy

compliance

Permission Control

Easily configure and assign different permission levels to users, requiring e-signatures when appropriate.

Audit Features

Comprehensive audit log system that records and reports all critical and configuration-management transactions such as document revisions, approvals, inactivation and user logins.

Configurations

Master configuration options allow users to modify system behavior according to laboratory requirements and practices.

Dynamic Automated Test Equipment (ATE) Scripting System

The MPS automation scripting system is a powerful tool with many advance features that simplify the automation of the most complex calibration procedures.

Control of Automated Test Equipment (ATE)

- MPS integrates the National Instruments VISA system to communicate with instruments via multiple interface types, such as GPIB, RS-232, USB, and Ethernet.

Dynamic Display of Instructions with Images

- The scripting system provides multiple methods for displaying rich text formatted (RTF) instructions and graphical images.

Multiple Forms of User Querying

- Query prompts allow users to enter values or select from a predetermined list of options. Multiple values can be requested and may include instructions or explanation of the values to be entered.

Dynamically Modify Data Sheets

- MPS has several commands that will dynamically modify data sheets to facilitate the use of generic data sheet templates. For example, you can prompt the user for such information as the specifications for a specific torque wrench. The values returned can then be used with a command to reconfigure all the test points to the nominal values and tolerances of the specified instrument.

Unlimited Global Variables

- You can create an unlimited number of global variables and name them as you see fit.

Wizards for Complex Command Configurations

- Many commands have wizards to assist the user in configuring command parameters.

Integrated String and Math Equation Systems

- The wizards for the math and string builder (complex string equation) commands are equation editors. These equation systems include a large number of built-in functions and support the use of variables.

Supports Sub-Procedures with Arguments and Local Variables

- The automation system supports the creation and use of sub-procedure that can take arguments (values passed in and out) and have their own local variables.

Supports Reusable Script Modules

- Script modules are bundles of commonly used procedures and automation objects such as script commands, instructions, global variables, and datasets. Script modules can be used as plugins in designing data sheet, thus greatly simplifying and reducing scripting time.

Supports an Unlimited Number of Datasets

- Datasets are basic two-dimensional spreadsheets that can be written to, read from, perform math operations on columns and rows, and can be independently saved to, or loaded from, an external file. The automation system allows users to create and configure as many dataset objects as required.

Automatic Support for Sampling and Processing of Measured Values

- The commands that apply measured values fully support sampling and automatically apply measured value formatting rules and determine if measurements are in or out of tolerance. The automation system automatically applies the samples/measured value to the currently active test point, calibration channel, and data mode (As Found/As Left).

See MOX in Action

Schedule a demo to see why MOX is trusted when quality and accuracy are mission critical.